Normal atmosphere contains between 20.8% and 21% oxygen. Less oxygen than this can impair respiration, causing an asphyxiation hazard. More oxygen than this presents a combustion risk.

The Occupational Safety and Health Administration (OSHA) defines an oxygen-deficient environment as any space containing less than 19.5% oxygen by volume. At this level, OSHA requires that employers provide workers with respiratory equipment, meaning that monitoring oxygen levels is crucial where oxygen displacement or consumption is possible.

Oxygen Levels

An oxygen-deficient atmosphere can cause immediate effects without obvious warning signs. Especially in confined spaces, it can take very little change in oxygen concentration to put workers at risk.

Inert Gases

In confined spaces that are potentially oxygen rich, inert gases are sometimes introduced to displace oxygen as a form of fire prevention. This demands careful monitoring to ensure that the atmosphere is not combustible but remains safely breathable.

| Atmospheric O2 Concentration | Possible Results |

|---|---|

| 20.9% | Normal |

| 19.0% | Minor adverse physiological effects |

| 16.0% | Impaired thinking, difficulty paying attention, reduced coordination, increased pulse and breathing rate |

| 14.0% | Abnormal fatigue when exerting self, mood swings, poor coordination, impaired judgment |

| 12.5% | Very poor judgment and coordination, nausea, vomiting, impaired respiration that may cause permanent heart damage |

| <10.0% | Confusion, inability to move, loss of consciousness, death |

In order for combustion to occur, three elements must exist:

- A fuel to be burned

- A source of oxygen

- A source of heat for ignition

Combustible Gases

Numerous gases used in industrial processes are combustible, including acetylene, butane, ethylene, methane, propane, and propylene. These gases are used for fuel as well as in processes ranging from plastic manufacturing to welding. Some give off no odor, and they have much different flashpoints, so monitoring instruments are needed to ensure safe atmospheric levels of each.

Oxygen Enrichment

OSHA defines an oxygen-enriched atmosphere as any space containing more than 23.5% oxygen by volume. This creates an increased hazard of fire or combustion.

There are 3 questions to ask when choosing the gas monitor that's right for your work.

- What types of gases should I be concerned about?

- What concentration levels present an emergency?

- How many potential gas sources are present and where are they located?

Fixed Gas Monitors

When gas is emitted from a specific source, as with a leak, fixed monitors continuously detect the air composition in that space.

Portable Gas Monitors

When there are multiple potential sources of gas or it’s generally present in the air, portable gas monitors are advisable to keep workers aware of the air composition wherever they’re working.

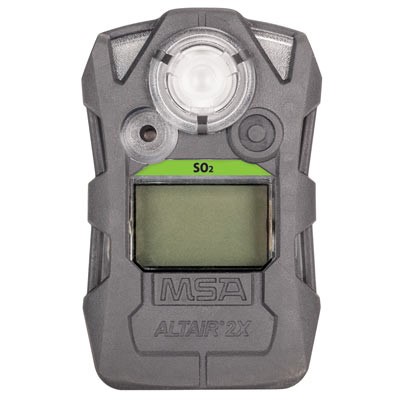

Single-Gas Monitors

These detect the presence of one specific gas. Used when workers expect to encounter one specific toxin much more commonly than others, such as carbon monoxide.

Multi-Gas Monitors

In situations where any number of gases may be present, such as demolishing buildings, or investigative situations such as unknown leaks or landfill monitoring, a multi-gas monitor is the safest option.

Combustible Gas Monitors

These measure not only the presence of a combustible gas in the air, but also whether that gas is in a sufficient concentration to ignite.

To ensure proper functioning of your gas monitor, calibration gas mixtures are used to test its detection accuracy. Gas monitors are susceptible to drift, gradually losing accuracy over time, which means that regularly testing your instruments is vital to ensure safe work. Knowing the types of calibration gases will help you better understand how to most effectively test your equipment.

- Zero Calibration Gases: These mixtures contain no flammable gases, nor the gas that the monitor detects. Inert gases like nitrogen are commonly used in these mixes

- Single Calibration Gases: Contain a known concentration of a specific gas that a single-gas monitor detects

- Span Calibration Gases: Contain known concentrations of multiple gases that a multi-gas monitor detects

Gas detectors generally require calibration and testing at least every six months to ensure reliable readings, although more frequent testing may be necessary depending on the type of monitor and its exposure to adverse conditions. If you want to ensure that your testing equipment functions at its best, the Würth Industry Technical Services Department can help! Our team of experts offers calibration, maintenance, and repair for both portable and fixed instruments. We also carry a deep catalog of equipment rentals that includes multi-gas monitors, 100% tested and calibrated prior to shipment. Contact our Technical Services Department to learn more at 1-800-677-0078 or rentalandservice@wurthindustry.com